When I was 14, I joined the Eastern Loggers. The group was building a sectional railroad inspired by a series of books call The Logging Railroad Era of Lumbering in Pennsylvania. The group had just formed, so I was getting in on the ground floor. This group taught me about modeling excellence, working with others, managing projects, and interacting with the public. I still look back at those years from age 14-35 with fondness and would like to share some of the past with you now.

The following material comes from what was narrowtracks.com

Introduction

Welcome to the Eastern Loggers Home Page a site devoted to the Eastern Loggers Model Railroad Club, its members, followers, and the railroads and industries that inspired it.

In 1981, Jerry Strangarity and John Burchnall founded the Eastern Loggers Model Railroad Club. The idea was to build a sectional layout based on the 13 book series, The Logging Railroad Era of Lumbering in Pennsylvania, by Walter Casler, Thomas Taber, and Benjamin Kline. A few years earlier, Jerry had built a diorama of a typical Pennsylvania Logging town. The club layout was a much larger version of the same theme.

The original layout design called for 6 sections to form a 10’x10′ layout. However, within a few months, the group expanded, adding two more modules to the design. Over the years, the layout has been improved, by the addition of backdrops, DCC, two more sections, and most recently staging yards.

Each year, the Eastern Loggers appear at the November Show, which is put on by division 7 of the Mid-Central region of the NMRA (Cincinnati). Besides that, the layout makes occasional appearances at other events such as Mini-Bunch meets, National Narrow Gauge Conventions, and NMRA conventions. We will be open for the 2003 Mid Central Region NMRA meet at the end of April.

Construction

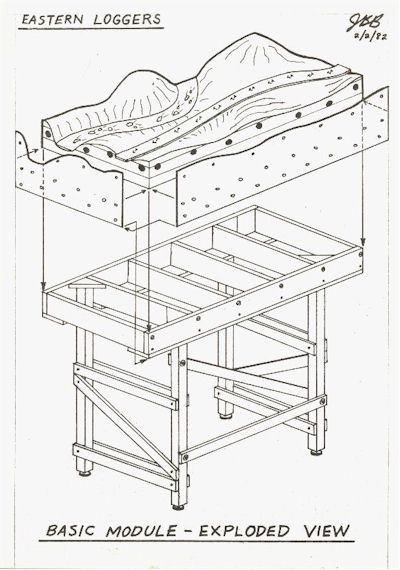

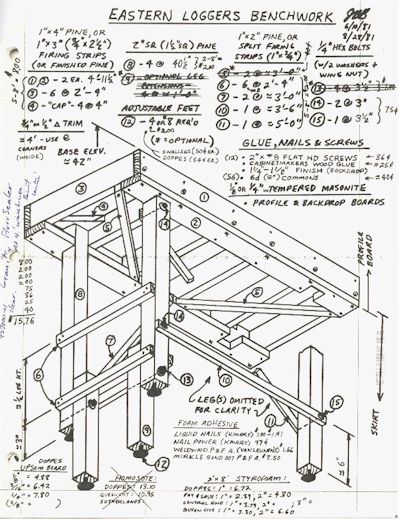

John Burchnall design the specification for sections. One of the innovative features of the construction was the use of foam board. John spent many years giving clinics about foam board, and now it is one of the leading/recommended techniques not just for lightweight module construction but also for home layout use. Bill Darnaby even credited John as providing his inspiration.

I must state that the Eastern Loggers used beaded foam (white), not blue or pink or green foam. The beaded foam is lighter and easier to carve than the more dense blue foam. However, beaded foam is not good for carving scenery. Beaded foam requires plaster on top. Other modelers such as Sam Swanson have done wonders carving high density blue foam into hills and rock formations without any plaster at all, keeping modules and layouts lighter and plaster free (Sames modeling techniques have been published in MR, NG&SLG, Light Iron Digest, etc….)

Here are specifications sheets

The Eastern Loggers layout is composed of modules. Each module consists of 5 major components:

- 2×2″ wood legs, which are self standing and fit in slot in the frame.

- 1×4″ “Inverted L-girder” frame. Actually, it is a true upright “L”.

- Foam Board for scenery and roadbed support. The grades for the roadbed are carved directly in to the foam and the roadbed is layed directly on top.

- 3/16″ or 1/4″ Upson board roadbed. At present, upson board is no longer available. Possible substitutes are Homabed, Luan Board (like the doors, not the plywood), or homosote. Grades carved directly into foam may have imperfections (dips and humps). A stiff roadbed is needed to smooth out the imperfections. Cork is too flexible to cover the dips, Homabed is questionable, upson board was perfect.

- 1/8″ Masonite fascia boards. The masonite is screwed and clued to the side of the module. Wood blocks are glued into the foam for screws. Not shown on the drawing are corner blocks. These are 1×2’s placed vertically into the corners of the module, they make the corners square.

Additional Notes:

Always use foam compatible glues when gluing layers of the foam.

The under view shows the slots where the legs slid into. Leg stops (4) prevent the legs from pushing directly against the foam. The cross brace (5) on the bottom of the module is not needed. The foam provides a sufficient stability. Note, the design provides for leg extensions.

After a few years of moving the modules to shows, it became clear that they were over built. The frame could have been significantly lighter, the 1×4’s were over kill. But they have lasted the test of time (30 years as of this writing).

One interesting happening was that Jerry Strangarity’s Sawmill module (our most delicate) was in an automobile accident. He was pulling through an intersection when a car ran the stop signs at 55 miles an hour, hit the rear of his car. First of all he and any passengers of his car were OK (I do not remember injuries in the other car either). However, the module was….well….better than expected. The wood frame was shattered and the masonite sites were broken loose, and all the white metal sawmill details were spread throughout the car. But the delicate structures were intact. The beaded foam seemed to have absorbed the blow…..

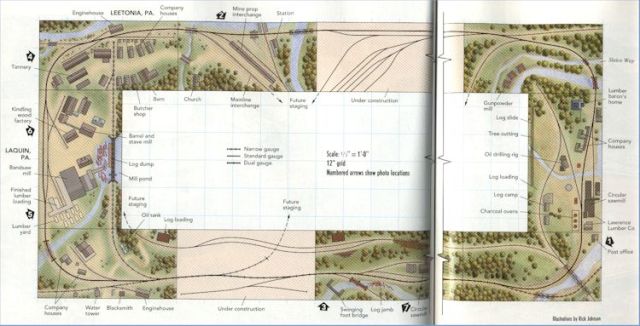

Trackplan – GMR 1997

For me, one of the greatest accomplishments for the Eastern Loggers was the appearance in the 1997 issue of Great Model Railroads. Here is the trackplan from that issue (Kalmbach gave permission to publish on my old web site, so assuming still OK to publish). To see the full article get the new DVD from Kalmbach (coming out soon).

For reference here is a listing of primary modeler (might not have been owner)

- Sawmill Complex (Laquin, PA)- Jerry Strangarity – Left most section

- Tannery (Leetonia, PA) – Paul Miklos – Upper left

- Mine Prop Interchange – David Keith – Upper, 2nd from left

- Wood Chemical Plant (Mayburg, PA) – Paul Miklos – Upper, 2nd from left

- Gunpowder mill (DuPont – Hagley, DE) – John Burchnall – Upper, right

- Switchback – Larry Pockrus – Right most section

- Highline bridge – John Burchnall – Lower right

- Rural Sawmill – Mike Tener – Lower 2nd from right

- High line log camp – Mike Merenes – Lower 2nd from left

- Sawmill Lumber stacks (theme changed after this article) – John Burchnall – Lower left

All sections were 30×60″ with the exception of the Sawmill complex that was 36×60″

Sawmill Complex

The sawmill complex was the premiere section of the layout. It was built by Jerry Strangarity. Jerry written a series of articles about his Pennsylvania logging town for RMC (various issues in the late 1970’s or early 1980’s). This section was imagined to be an extension of that diorama. The diorama was never part of the Eastern Loggers layout.

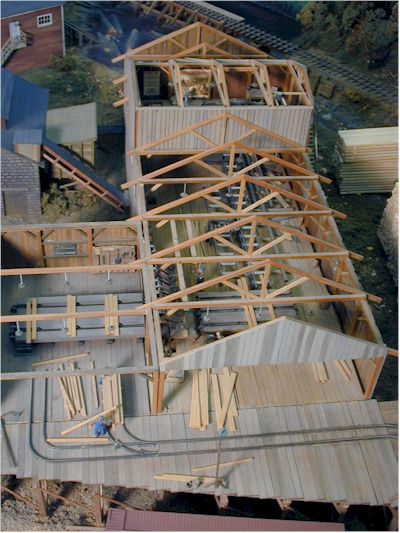

The interior of the Laquin bandsaw mill. Jerry Strangarity built the complex using board by board construction. The interior details are Keystone detail parts

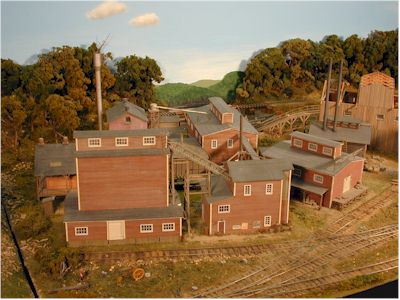

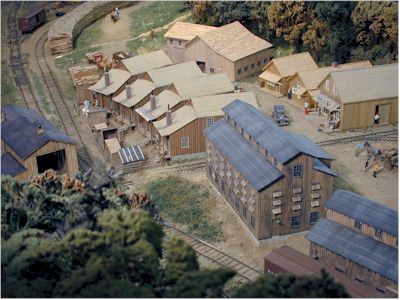

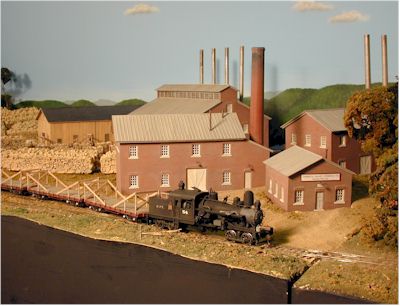

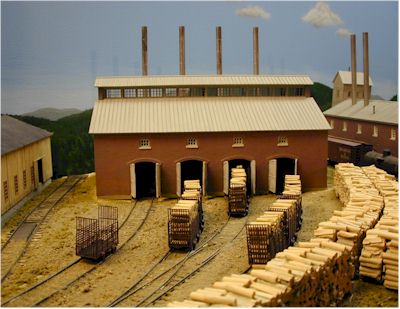

The focal point of the Eastern Loggers Layout is a large Mill Complex. The center piece of the scene is the band saw mill which features full interior. From the pond there is a second slip jack that serves the barrel and stave mill. The final structure on the section is the kindling wood factory. All of the structures were built by Jerry Stangarity. He placed the structure based on a photo of the town of Laquin, PA.

The roof’s of the band sawmill can be removed to expose the interior. The second store room is occupied by the saw filer. The filer services the hundreds of teeth on the blades for the band saw. Saw dust is swept through the floor of the sawmill, then put on a conveyor which takes it to the boiler house. Part of the boiler house and conveyor are just visible to the left of the mill. The mill pond and the log dump are in the background.

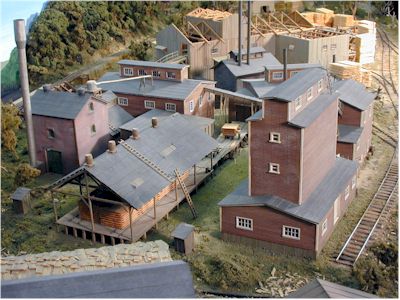

Here is an overview of the mill complex. At right is the kindling wood factory, to the left is the drying shed for the barrels and staves, at the rear is the band sawmill.

Elevated trestles are used to move the sawn wood to the lumber yard. Electricity for the lamps is provided by generators hooked up to the sawmills engine. The engines which powered the belts were located under the sawmill floor. Actually, the sawmill floor was raised off the ground.

The loading dock is for the barrel and stave mill. At left is the kindling wood factory. The barrels weren’t assembled prior to shipping, the recipient would assemble them on at their site.

A good view of the kindling wood factory. The wood was cut in the smaller building at right. Steam heat was used to dry the wood. The tall building at the right had pipes through which the steam passed, drying the wood. The conveyor between the two buildings transferred the wood to the top of the drying building.

After these photos were taken, Paul Miklos expanded the sawmill’s lumber yard to the adjacent module. The new yard wraps around the Mountain and seem to head up the valley like many prototype photos from the PA logging books. Paul hand cut much of the lumber in those stacks which are individual stacks up to 30 HO feet high! Paul is a nut….

Tannery

The tannery module had a few owners and many contributors to the final scene. When Ed Heage was owner, he adopted Leetonia (see book 4 of the PA logging series) as the inspiration. He built a tannery building and the company store. However, he never completed the tannery complex before leaving the club for other activities, so only the store remains of his work. The following photos show the combined work of several members.

Overview of tannery module is inspired by photo, page 4xx book #4 of the Logging Railroad Era of Lumbering in Pennsylvania. The trees in the photos of this photo are part of the section. Ed added a steep hillside to the section, so that one could look over the trees in a similar fashion to a photo in the PA logging book. It worked out well, and forced viewers to look around the scene from specific angles.

The tannery and surrounding company town are inspired by the town of Leetonia, PA. Leetonia featured a large tannery, sawmill, town, and railroad facilities. The placement of the buildings on the tannery module loosely follow the placement of buildings in lower portion of Leetonia. The major difference is that the model tannery is on the opposite end of town.

The majority of the modeling on this section was done by Paul Miklos. The exceptions being the company houses which were built by Clarke O’Byrne, the company store built by Ed Heeg, and the CPL office and Post Office built by David Keith.

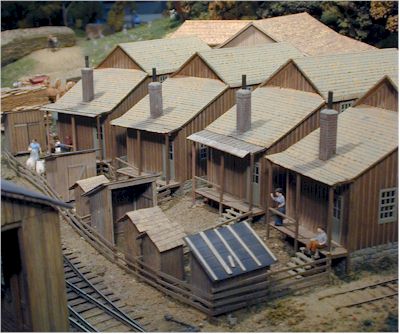

The company houses were built by Clarke O’bern. Paul Miklos built the privies, sheds, and added the details.

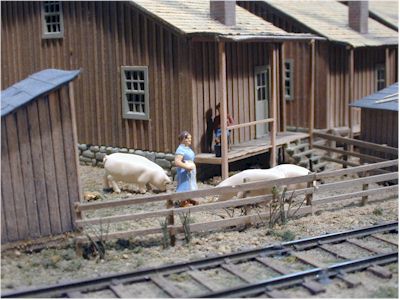

Farm animals were common in Leetonia. This house is the exception, having pigs. Most families had cows. The cows would graze in the pastures above town, returning each twice a day for milking.

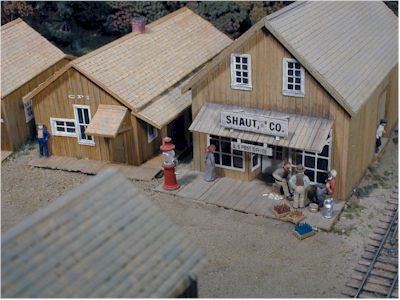

The Shaut Company store, built by Ed Heage, was a gathering point for the men of Leetonia. On payday, the men would line up at the Horizontal window of the CPL office.

The engine house has a full interior. To make it easy to see, the side wall can be removed. The bark stacks extended onto the interchange module to blend the scenes.

Wood Chemical Plant (Factory)

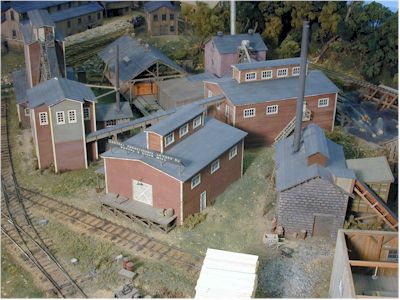

The chemical plant is inspired by the Tionesta Valley Chemical Companies plant at Mayburg, PA. The prototype plant was one for largest acetic acid plants in Pennsylvania. It featured 12 retorts and was made out of brick instead of the more common metal siding. Inside a chemical plant, wood is distilled, to capture the gasses that escape. The most important product of the distillation process was the acetic acid or acetate of lime. Acetic acid was used as a fixative for dyes, very important during World War I. Another product that resulted from the distillation process was charcoal.

The model plant is significantly compressed from the prototype. It only features 4 retorts (tracks) and does not feature the cooling chambers and sheds at the behind the retort building. There just was not enough space. All of the buildings, cord wood stacks, and rack cars were built by Paul Miklos.

The retort building is at the rear of this photo. The other large buildings contain the still house. The stills were used to condense and separate the gasses. Paul also build the 30′ flat cars with racks on top. Throughout Pennsylvania, Cord wood was hauled in cars similar to these.

Other Sections

At this time, I do not have any photos of the other modules ready for publication. Time permitting, I can update this post again…

Train Control – DC to DCC – No Shorts!

John Burchnall had designed a complex 8 CAB DC system using rotary switches. A CAB for each original module. It worked but was a lot of wiring that we never really used.

In 1994 Lenz DCC had been released and was being sold here in town by John Mann (of Mann-Made products fame & CTC-16 and such). I was single, not married and had money. So I purchased a Lenz system and 4 decoders (LS-100’s) that I installed into AHM heislers during the two weeks before biggest show of the year. I also made a throttle bus that could be plugged onto the layout (6 stations, no plug and play yet). The first time the system was run on the layout, was at the show….It all worked perfectly and we never looked back to DC again. It was a few years before other display layouts began appearing with DCC control.

Later we switched to Digitrax because it had radio control and because I thought it was time for the club to invest in it’s own DCC system. The radio control was never as reliable as our plug in Lenz LH-100 throttles. The more complex digitrax throttles made it hard to work the layout and steal engines (commonly required when operating a show layout). Actually, Lenz let’s multiple throttles control a locomotive, no “stealing”. For the club it would have been better to stay Lenz (I think Digitrax has gotten better and now has simpler UT throttles with radio control….so matters might not be so complicated today)

One special feature designed into the layout was stopping blocks. These are locomotive length sections of track beyond each turnout frog. The stopping blocks prevented trains entering a wrongly thrown turnout from fouling a turnout or worse creating a short. These stopping blocks are one reason the Eastern Loggers layout worked well when the switch to DCC happened. The layout rarely suffered from shutdowns due to shorts. Honestly it was not till several years later that I understood why other layouts (not having stopping blocks) needed short circuit detection.

Listing of PA Logging Books

The Logging Railroad Era of Lumbering in Pennsylvania by Benjamin Kline Jr, Walter Casler, and Thomas Taber III. A series of 13 books about lumbering in Pennsylvania. Additionally, Kline and Taber have each written additional books about Pennsylvania Lumbering.

- Pitch Pine and Prop Timber by Kline

- “Wild Catting” on the Mountain by Kline

- Ghost Lumber Towns of Central Pennsylvania by Taber

- Sunset Along Susquehanna Waters by Taber

- The Goodyears – An Empire in the Hemlocks by Taber

- Whining Saws and Squealing Flanges by Casler

- Sawmills Among the Derricks by Taber

- Tionesta Valley by Casler

- Teddy Collins Empire by Casler

- Tanbark, Alcohol, and Lumber by Taber

- Allegheny Valley Logging Railroads by Casler

- Dinkies, Dams, and Sawdust by Kline

- “Stemwinders” in the Laurel Highlands by Kline

Books 1, 2, 12, & 13 by Kline were printed recently by the Railroad Museum of Pennsylvania. They are available from the museum for about $10 US each. Book 3, 4, 5, 7, and 10 have also been reprinted recently enough to be available. The 2nd Floor Bookstore at the Strasburg Railroad has these books written by Tabor. The books written by Casler are not being sold new. Check Ebay or used book sources.

In addition to these books, Tabor went on to publish a few other books about specific logging railroads and shortlines of Pennsylvania. He was still alive in the late 1990’s and was still doing his own railroad research. All of the Kline photos and Klines letters to Tabor and Casler are in the collections of the Railroad Museum of Pennsylvania.

Pennsylvania logging was different from West Virginia, Michigan or West Coast and the books above are a great way to learn the specifics of Pennsylvania logging.

Parting Comments

By 2009, marriage, a son, and a move to the other side of town, I had willingly limited my participation in the club; so I sold my section to another member of the club, ending 20+ years of active involvement. It was not an easy choice but the reality, I had moved on to Sn2 Free-mo and trying to get back to my Dream home layout.

My years as an eastern logger were a great experience for me. I look back at them fondly. I must thank my parents for encouraging me to become involved at the age of 14. For the first 2 years (until I could drive) my dad would take me to meetings. Additionally, when I joined, he already had the set of the logging books (he came from California, what was he doing with a set of books based on PA logging?). His railroad library fueled my fascination for two of my favorite prototypes (PA Logging and Maine 2-Foot).

I’d also like to thank of the Eastern Loggers for letting me, at a young age, partake in the club as an equal not as a junior. My involvement with the club formed me as a person, in the hobby, home, and most importantly professionally.

Pingback: Friends, Suprise, and a goal! | Sn2 Modeler

Pingback: TNT in the Iron Age | Sn2 Modeler

Excellent article. What logging company did the group follow? I see CPL on the locomotives

Larry, thanks for your interest. We did not have an official lumber company or railroad to follow. In later years several of us decided to adopt existing entities. CPL stands for Central Pennsylvania Lumber Co. If my memory is correct, CPL was associated to the US Tanning. The CPL had operations all over the state. We also had a some locos and cars lettered for the Sheffield and Tionesta.

I have always admired the work that was done on the Eastern Loggers layout. My sawmill is almost the same as Jerry built for the layout with more details especially in the sorting area. It took 102 points at the NMRA in Cincy in 05. I will be using the layout to show how to model logging railroads at my clinic in Springfield, Mass in January for the Amherst show. Much obliged for the company name.

Pingback: Eastern Loggers Videos | Sn2 Modeler

Pingback: Starting homasote spline roadbed (rather than foam board) | Sn2 Modeler

Pingback: Eastern Loggers Layout – Goes to a museum | HAVOC

Pingback: Honored! My work is in a museum | Sn2 Modeler